High Precision Temperature Control Application Case on Bioreactors in Medical Projects

2024-10-10

2024-10-10

Application Industry: Biopharmaceutical

Application Models: AI-826, replacing Omron E5CC controllers.

Process Overview:

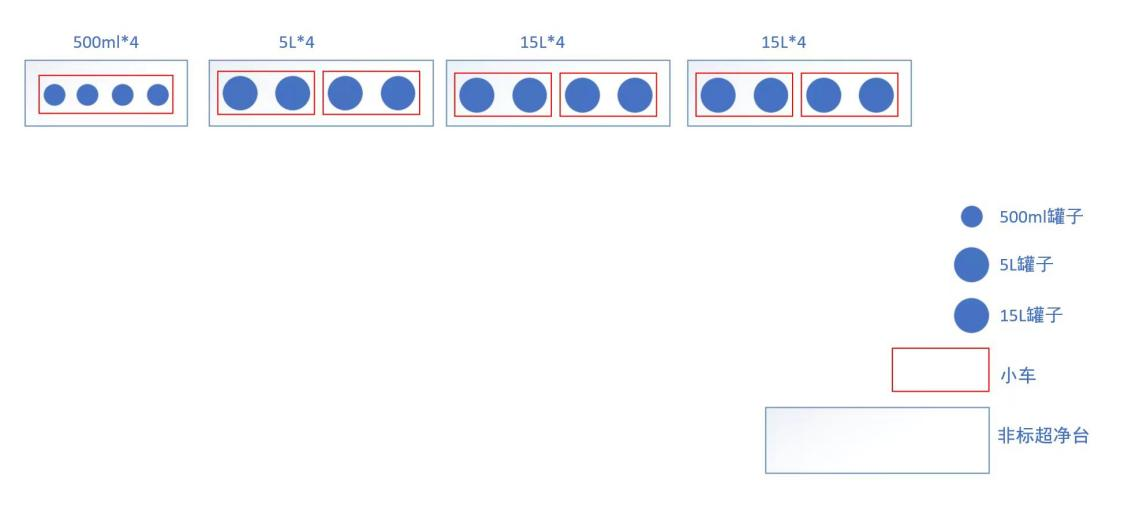

Each bioreactor is controlled by one temperature controller, with a production line typically requiring 16 temperature controllers to maintain an operational temperature of approximately 37°C.

The ambient working temperature ranges from 20 to 30°C. Temperature measurements are taken using PT1000 probes to ensure precise control. Operations usually last for about one week, during which the more accurate the temperature control is, the more stable and higher quality the product reactions will be.

On-Site Application Details:

The liquids being heated in the bioreactors vary each time and require long-term heating, necessitating stable control with minimal temperature fluctuations. On-site, it is necessary for the temperature controller to support multiple communication protocols for easy integration with upper-level computers.

Problems Solved for Customers:

Previously, customers used Omron controllers but sought domestic alternatives capable of high-precision control with PT1000 input. The Yudian AI-826 precisely controls the heating liquid at 37°C. After adjusting the PID parameters, the initial heating overshoot was only 0.3°C, followed by long-term stability around 37°C. Considering the limited space within the customer's equipment cabinet, the rail-mounted design of the Yudian AI-826 saves space.

Customer Feedback:

The after-sales service and technical response from Yudian are timely and patient. After self-tuning and minor adjustments, the AI-826 can maintain small temperature overshoots across different liquids and operate stably over extended periods. The universal communication protocols also facilitate easier overall equipment debugging and perfect integration with other upper-level computers.

TOP