Application of Yudian Multi-Channel Temperature Control Modules in Multi-Lane Packaging Machines

2024-09-19

2024-09-19

Application Industry: Packaging Machinery Industry

Product Models Used: AI-7048, AI-8148

Process Overview:

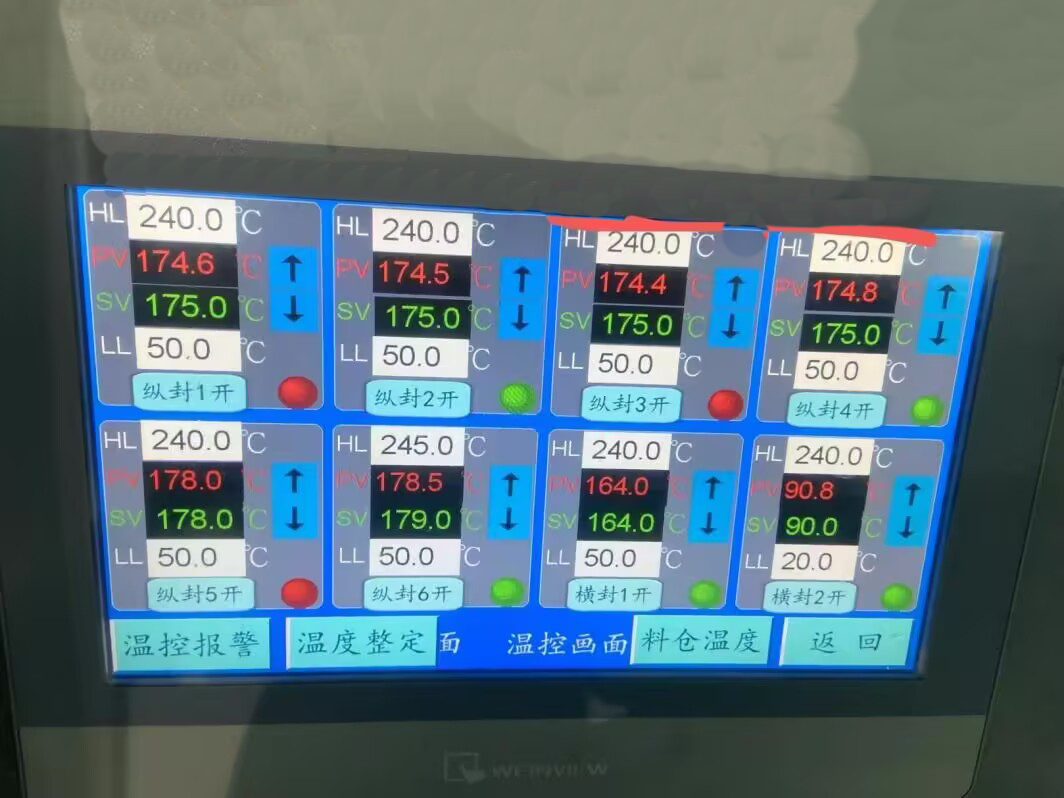

Multi-lane packaging machines can be further categorized into multi-lane powder packaging machines, multi-lane liquid packaging machines, and multi-lane granule packaging machines. For different materials, varying temperatures are required to seal the packaging materials. Inaccurate temperature control or overshooting can cause issues such as burning or wrinkling of aluminum films in the packaging material, while excessively low temperatures may result in poor sealing. The Yudian four-channel temperature control modules, models AI-7048D71J7G5G5L21S2 and AI-8148GD71J7G5G5L21S2-24VDC, allow for pre-setting of heat-sealing temperatures and automatic temperature control, ensuring good thermal balance. These modules are suitable for various packaging materials, ensuring that the bag seals are tight, flat, and aesthetically pleasing. Additionally, they feature RS485 communication functionality, enabling connection to a host computer. This centralizes instrument debugging and control on the central control screen, simplifying settings and temperature display, significantly saving installation space and commissioning time.

Specific Field Application Description:

Yudian temperature controllers replace traditional PLC control, ensuring stable sealing temperatures for equipment, improving the tightness, flatness, and aesthetic quality of product seals. With channel functionality enabling communication with the host computer's touch screen, the operation and debugging process is greatly simplified, making it easy to understand and operate.

Problems Solved for Customers:

In the early stages, the customer used PLC-based temperature control, which required self-programming. Additionally, the PID control effects from the programmed logic were not well understood, leading to significant waste of raw materials during debugging and increasing operational costs. After introducing Yudian instruments, temperature uniformity was ensured, allowing for the full utilization of raw materials.

Value Delivered to Customers:

With the customer's original PLC-based temperature control solution, whenever control issues arose, it was necessary to inspect and rewrite the program. After switching to Yudian’s products, when temperature fluctuations occur, only a PID self-tuning operation is required. This not only improves efficiency but also enhances equipment quality, boosting the competitiveness of the customer’s products.

Customer Feedback:

The product demonstrates reliable and stable control performance, with the default PID values from the factory meeting most temperature control requirements. The module’s compact and aesthetically pleasing design occupies minimal space, and the quick-connect terminal wiring is simple and fast to operate. The product features a high level of automation and is easy to maintain.

TOP