Application of Yudian AI Instruments in Electric Heat Tracing Devices for Ice Removal in Power Plant Chimneys

2020-08-06

2020-08-06

Source: China Instrumentation Magazine

Authors: Huang Dengfeng1, Jiang Yanfang2, Chen Jingjie2

(1 Wuhan Yikong Automation Technology Co., Ltd.; 2 Xiamen Yudian Automation Technology Co., Ltd.)

Abstract:For the chimney de-icing electric heat tracing device which requires high reliability, stability and accuracy of temperature control, Yudian AI intelligent temperature control instrument was selected, and the application and related parameter setting problems were introduced.

Key words:Electric heat tracing device for chimney deicing ;Yudian AI instrument

1 Introduction

For thermal power plants, the wet flue gas desulfurization (FGD) technology is the primary measure to control sulfur dioxide (SO2) emissions. After passing through the mist eliminator in the wet FGD system, the clean flue gas carries water droplets (≥20μm) at a concentration of approximately 75mg/m³ (standard state, dry basis). As the mist eliminator's operating time increases and its efficiency decreases, the amount of water droplets carried by the clean flue gas after passing through the mist eliminator will also increase. Additionally, the water vapor content at the outlet of the absorption tower after desulfurization is around 75mg/m³. In cold regions during winter, outdoor temperatures can drop as low as -30°C. For desulfurization systems without a GGH (Gas-Gas Heater), the clean flue gas carrying water droplets and water vapor is discharged into the atmosphere through the chimney. When the clean flue gas exits the chimney and enters the atmosphere, its temperature drops sharply from approximately 45°C to around -30°C. Some of the water droplets and water vapor carried by the flue gas freeze on the chimney crown during diffusion, causing ice buildup. In severe cases, the thickness of the ice on the chimney crown can exceed 1 meter, with a height of up to 5 meters and a volume reaching tens of cubic meters. The weight of the ice on the chimney crown can reach several dozen tons, seriously affecting the structural safety of the chimney. If the ice falls from the chimney crown, it could cause severe damage to the desulfurization equipment below the chimney and pose a serious safety risk to personnel passing by, with potentially dire consequences.

2 Requirements and Control for Ice Prevention

A certain coal gangue power generation company (Phase I project) operates two 300MW units equipped with two 1065t/h circulating fluidized bed boilers. The units were commissioned for commercial operation in December 2009 and May 2010, respectively. The two units share a single reinforced concrete chimney, which is 210 meters tall with an inner diameter of 8 meters at the outlet.

2.1 Flue Gas Operating Conditions After Desulfurization Retrofit

The 2×300MW units in this project use the wet FGD process without a GGH. The operating conditions of the chimney are as follows: when the desulfurization facilities of both units or one unit are operating normally, the calculated flue gas temperature ranges from 30°C to 70°C.

2.2 Requirements

To ensure that no ice forms above 203.75 meters of the chimney under extreme cold weather conditions (-30°C) and plume wash-down conditions, an anti-icing heating system is installed at the chimney outlet. To eliminate production safety hazards caused by ice formation at the chimney crown, the following requirements must be met:

(1) Ensure that the chimney outlet and the ladder at the chimney outlet do not freeze during winter;

(2) Prevent secondary icing on the platform;

(3) Establish four heating zones around the circumference of the chimney. Each heating zone is powered and temperature-controlled independently, with partition points designated by the owner;

(4) Anti-icing is divided into four heating zones. Users can adjust the heating areas based on temperature changes to reduce unnecessary energy consumption.

3 Solution

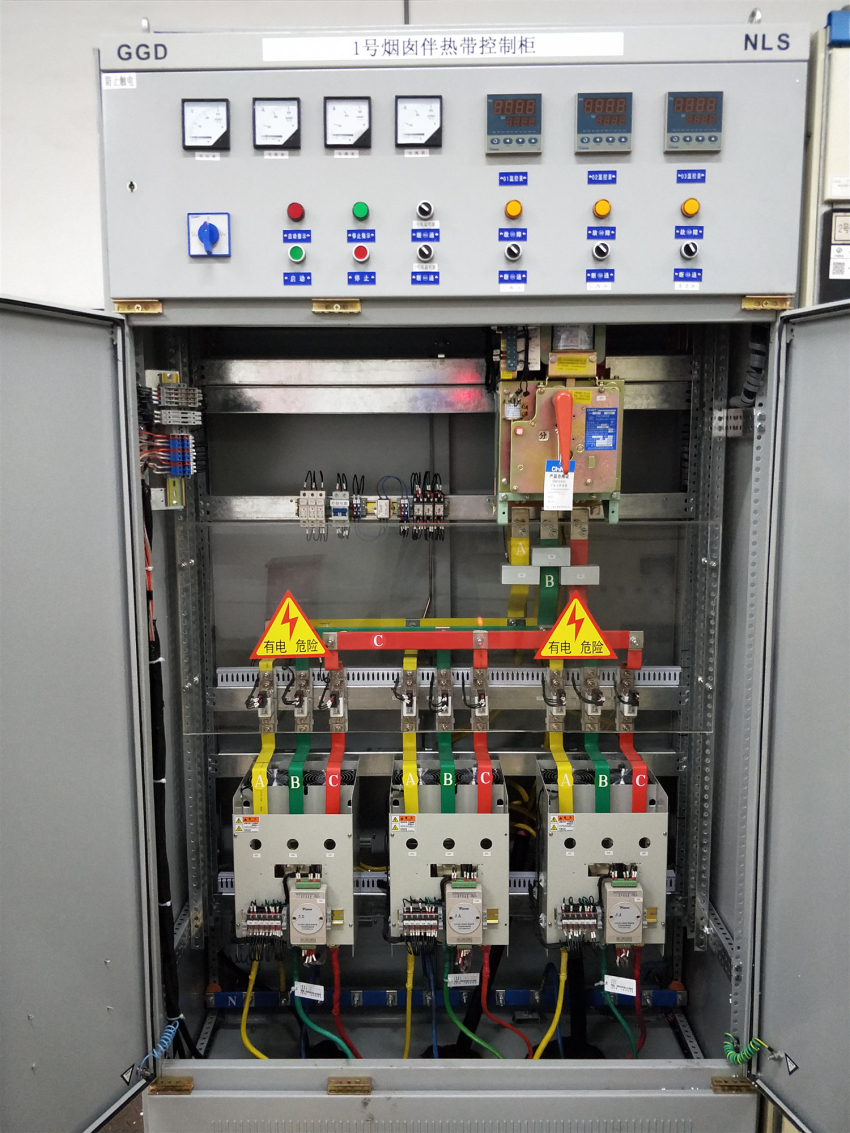

The entire electric heat tracing de-icing device consists of an intelligent temperature control cabinet, junction boxes, plate-type electric heaters, connecting cables, and related accessories. The control cabinet system includes a temperature controller, SCR three-phase power regulator, fuses, and circuit breakers. The cabinet dimensions are: 1200mm × 2000mm × 600mm, as shown in Figure 1.

Figure 1

3.1 Intelligent Temperature Control Instrument

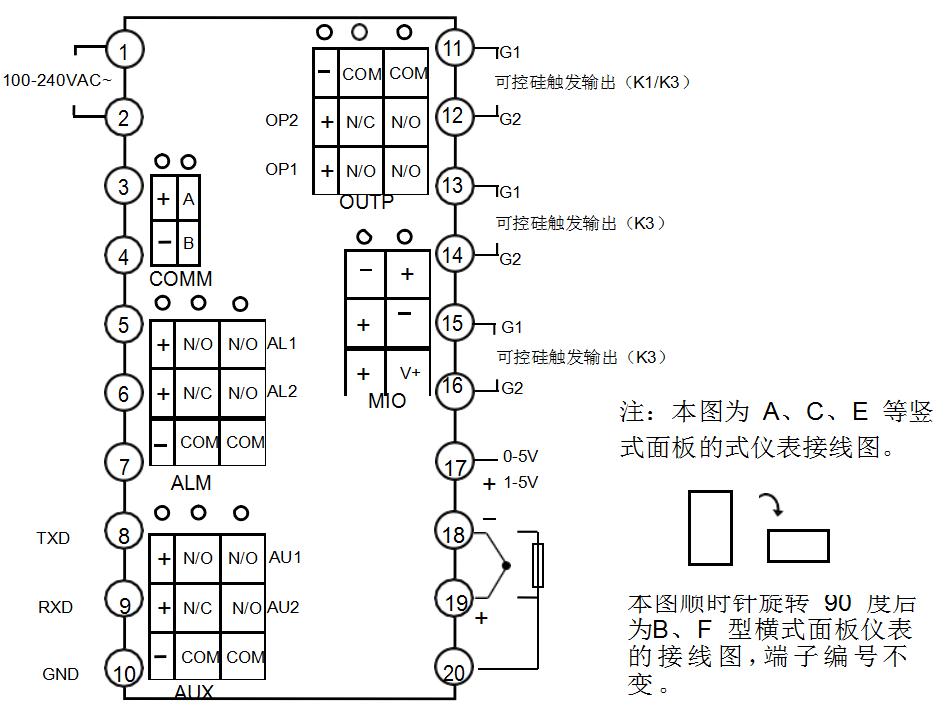

The intelligent temperature control instrument selected is the AI-719AX3L2S4 precision artificial intelligence industrial regulator from Xiamen Yudian Automation Technology Co., Ltd. The AI-719/719P series instruments are designed with energy-saving and environmental protection in mind, featuring extremely low temperature drift and minimal power consumption. The overall typical temperature drift is usually less than 25PPm/℃. Compared to ordinary temperature control instruments, these low-drift instruments exhibit smaller changes in measured temperature due to variations in ambient temperature. High-precision instruments, thanks to their low temperature drift, are more energy-efficient than lower-precision ones. For example, assuming a sintering temperature range of 1000–1010°C for a certain ceramic material, a common instrument on the market may have a temperature drift of approximately ±5°C (caused by seasonal and diurnal ambient temperature changes). Therefore, the instrument would need to be set at 1005°C (temperature variation range: 1000–1010°C) to maintain normal production under varying ambient temperatures. However, the AI-719/719P instrument reduces temperature drift to within ±1°C, allowing stable production when set at 1001°C (temperature variation range: 1000–1002°C). This lowers the average furnace temperature by 4°C. The lower the average temperature of an industrial furnace, the less energy it consumes. Simply reducing temperature drift can save 0.4%–0.6% of energy, stabilize product quality, reduce color differences, and further decrease energy consumption.

For nonlinear load high-temperature furnaces, their resistance changes drastically with temperature. Taking silicon molybdenum rods as an example, their resistance at room temperature is only about 6% of that at 1600°C. If the output power of the instrument is not limited or adjusted, two problems may arise. First, during low-temperature startup, excessive current in the electric furnace may exceed the allowable load of the power grid, thyristors, and transformers, potentially damaging the thyristors, furnace, and transformer or causing the power grid to trip. Additionally, since the furnace's power differs by more than 10 times between low and high-temperature zones for the same output, the proportional band P in the PID parameters would need to vary by more than 10 times across different temperatures to achieve precise temperature control in both low and high-temperature zones.

When used for silicon molybdenum rod furnaces, the following settings can be applied:

A00=1, A01=1050, A02=100.0; A03=1500; A04=750.0

d00=120.0; d01=1100, d02=2000

The instrument wiring diagram is shown in Figure 2:

3.2 SCR Three-Phase Power Regulator

The SCR three-phase power regulator is a high-power thyristor module independently developed and produced by Wuhan Yikong Automation Technology Co., Ltd. It integrates three-phase voltage regulation and power regulation modes, featuring automatic phase identification, soft start upon power-up, soft shutdown, and overheating protection for the heat sink. It is suitable for both resistive and inductive loads.

3.3 Plate-Type Electric Heater

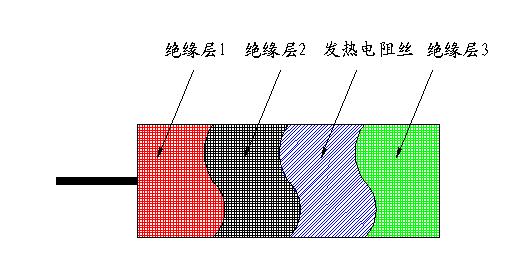

The plate-type electric heater must comply with standard specifications and exhibit excellent corrosion resistance. Silicone rubber heating plates have near constant power characteristics, with power variations of no more than 5% across different temperatures. The insulation performance indicators of the heating plates are as follows: at room temperature and relative humidity not exceeding 80%, the insulation resistance is greater than 100M ohms at 500V, and it can withstand 1500V for 1 minute without breakdown. As shown in Figure 3.

Figure 3

4 Conclusion

After the installation of the electric heat tracing de-icing device for the chimney, all technical indicators met the design standards. When the outdoor ambient temperature was -40°C, the surface temperature of the electric heating film remained around 45°C. Meanwhile, at an ambient temperature of 25°C, the Yudian AI-719A instrument demonstrated precise temperature control, maintaining the temperature consistently between 105°C and 115°C. After operating through the severe cold of winter, no icing occurred on the outer wall of the chimney outlet, and the system performed well. This solution reduced the system's operating costs and received positive feedback from the customer.

TOP